Has it ever occurred to you that since the invention of paper, the seemingly commonplace, insignificant and dispensable paper, all made with roughly the same processes and materials, has carried the weight of human culture and history for 2,000 years?

"What is paper?"

"Will we no longer need paper if we stop writing one day?"

We realized that we actually know little about this essential item in life when we started asking ourselves this. In order to find the answer, we came to Puli in Nantou County, papermaking capital in Taiwan for the last half century, seeking to see paper for what it really is from the very beginning.

//

Interview & text—Ho Man-Hsuan, Chiang Chen-an Still Photographer—Lee Ying-hsia English Translation—Chen Yi-hsuan

Home of manual papermaking in Taiwan:

Puli, a place of pure water supply.

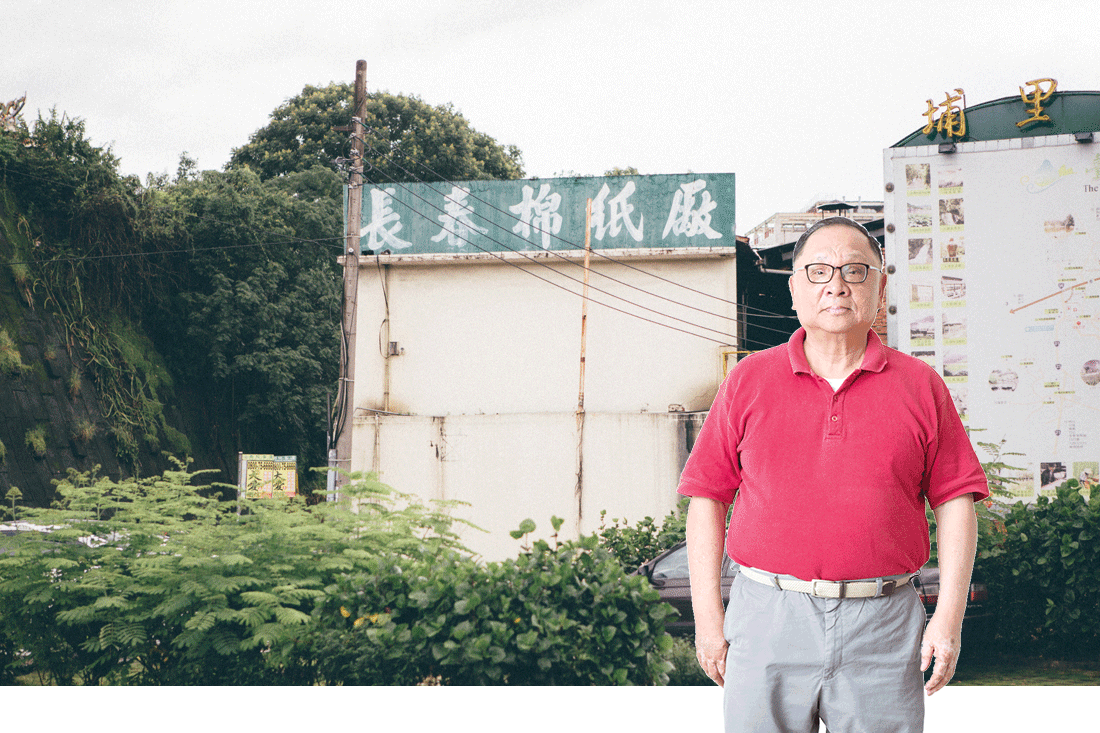

Chang Chuen Cotton Paper Mill

─

Founded in 1958 by Chen Su-ho, Chang Chuen Cotton Paper Mill entered into cooperation with Japan's Hirose Paper Mfg. Co. Ltd. in 1968 to set up Chung Rhy Specialty Paper Mfg. Co. Ltd.. In 1973, Ever Prosperous Co. Ltd. was established, and Suho Paper Memorial Museum was launched in 1995. Chang Chuen Cotton Paper Mill is a family-run business spanning the areas of traditional handmade paper, technology industry paper, paper for cultural purposes, papermaking materials, and paper art promotion. Dedicated to enhance the visibility of paper in culture, industry, and production, the company is testament to the development of local papermaking industry over the last 60 years.

Raw materials

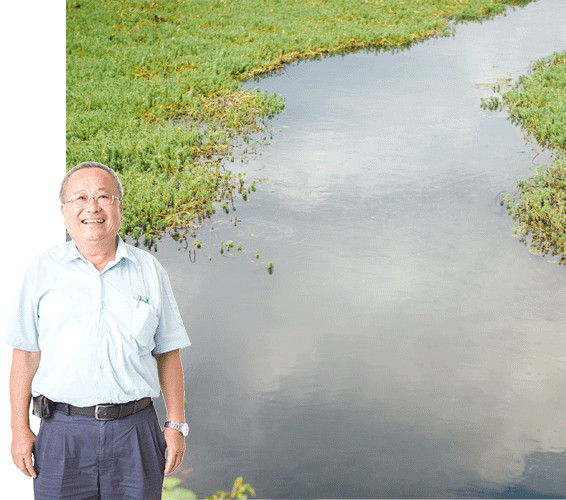

Huang Chuang-chin, assistant manager of Chang Chuen Cotton Paper Mill

Xuãn paper is mainly made from Wikstroemia bark, while Mián paper from kozo (mulberry) bark. The two materials require different cultivation and processing methods, but there is one thing in common in turning them into paper: clean water.

STEP 1. Soaking and Cooking

The bark is soaked in water for 8 hours and then cooked for 8-24 hours to thoroughly soften the fibers and remove unwanted ingredients such as lignin and resin.

STEP 2. Washing

The cooked bark is soaked and washed in a tub to further remove unwanted ingredients.(Click to watch the vedio)

STEP 3. Screening

Impurities are removed manually.(Click to watch the vedio)

STEP 4. Beating

A beater is used to pound fibers from cooked plant to make pulp, which is then mixed with other materials in accordance with recipes for different paper types.

STEP 5. Vatting

The pulp mixture is added with water in a vat. Manual vatting requires a three-step process of dipping, thickening and refining. A screen—a bamboo mold and deckle—is dipped into the vat to pick up a layer of pulp on the mold surface. The vatman then shakes it from side to side to settle the fibers evenly and drains the water through the screen. A wet sheet of paper comes into being as a thin layer of interlaced fibers materializes on the mold.(Click to watch the vedio)

STEP 6. Couching

Removing the deckle from the mold, the coucher uses a nylon string to lift the paper together with the couching sheet(抄紙簾). After stacking the paper on top of each other, the coucher removes the sheet and repeats the same process, building up a repeated sandwich, or "post."(Click to watch the vedio)

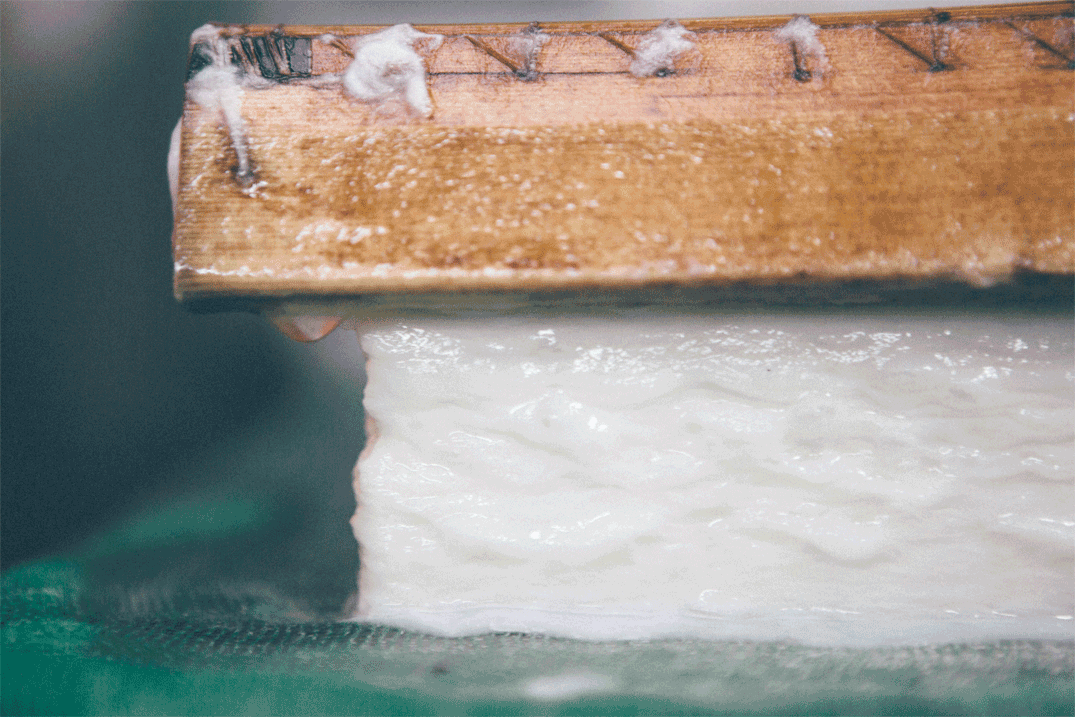

STEP 7. Pressing

A large wooden press is used to expel excess water from the stack of paper, aiming to reduce water from over 95% to 60% in the pressed post. When the process is completed, the posts are ready for drying.

STEP 8. Drying

Pressed papers are lifted one by one and placed on a 85°C drying surface, and then evened out carefully with a brush by the papermaker.(Click to watch the vedio)

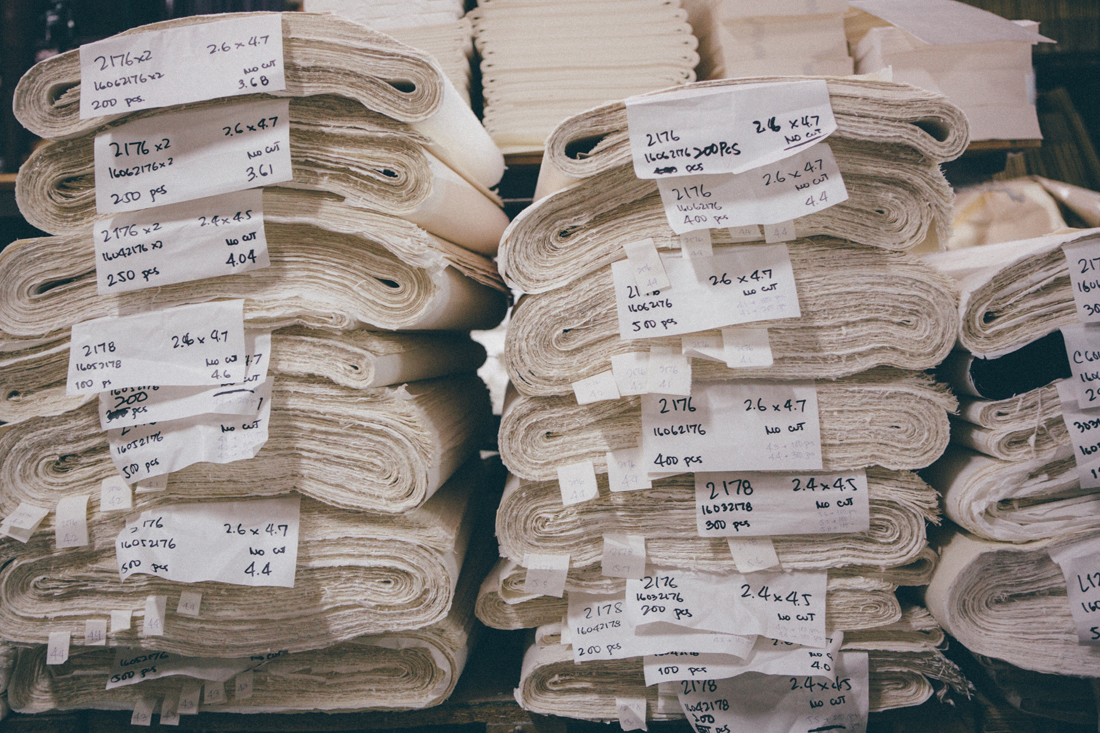

STEP 9. Quality Check

Finished products are checked, sorted, cut and packaged by manual labor.

【Traditional handmade paper in Taiwan 】

Puli, Nantou County

Chang Chuen Cotton Paper Mill

Manual papermaking is a cultural legacy,

which we have strived to uphold at any cost,

for when we stop, it will be gone forever.

——Chen Tao-Sheng, Chairman of Chang Chuen Cotton Paper Mill and Chung Rhy Specialty Paper Mfg. Co. Ltd..

Click to buy "Fine Writing Papers"

The best way to keep the tradition of handmade paper alive is to keep using it.

Fine Writing Papers+Journey of Paper

(special issue by okapi.books.com.tw)

" Fine Writing Papers" is compiled by Suho Memorial Paper Culture Foundation, comprising papers made from bamboo and wood pulp, pineapple and synthetic fibers, kozo (mulberry) bark and grains. Manufacturing technologies range from manual vatting to machine production, with origins from Finland, Japan, the U.K., and Taiwan. Also included in this pack are three vintage, out-of-circulation local handmade papers from more than 30 years ago.

Find the paper just for you, making it a need that lasts a lifetime.

回文章列表